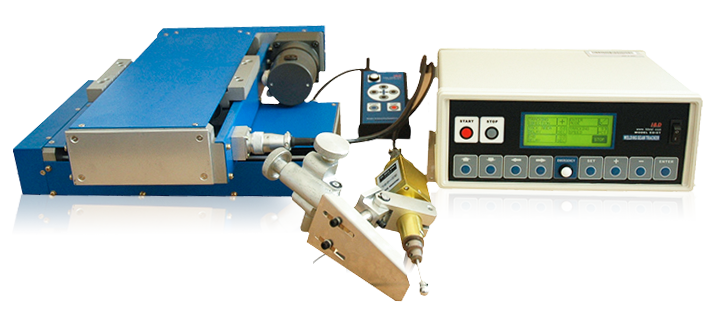

Welding carriage: the main body of auto welding carriage.

② Power adapter: AC 220V turn AC 36V, providing safe low voltage electric for carriage.

③ Control box: Control the move and swing of carriage.

④ Flexible track: Be adsorbed on the work piece and for the carriage movement.

There are two clutch handles on the main body of carriage, and they are hold clutch and drive

clutch handle respectively. (See figure below)

Drive clutch handle is walking switch between the motor and the drive gear. It must be closed

when carriage work and you can move the carriage manually when open. Closed hold clutch can

make the carriage hold the track tightly, and it must be closed before running carriage. The

carriage will loosen the track when open it and you can remove the main body easily.

Counterclockwise rotation of the clutch is closed, clockwise rotation is open, and switch travel

is 90 degrees.

ED-100B-P Carriage

1

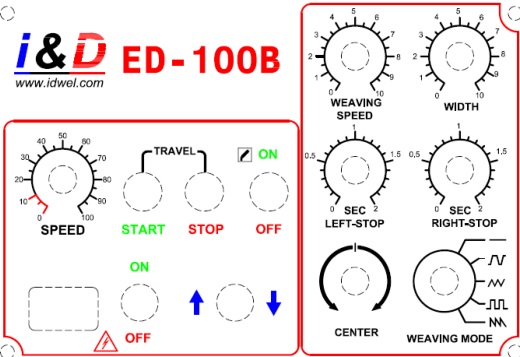

5. Control panel:

1) Torch ON / OFF selector switch: Select OFF, and then the carriage will not travel when you press

START button.

2) UP/DOWN selector switch: The selector switch of travel direction;

3) Start button : carriage began to travel when press it;

4) Stop button: carriage stop traveling when press it;

5) Speed adjust knob: clockwise rotation is increase;

6) Power switch: power ON / OFF;

ED-100B-P Carriage

2

7) Oscillator control parts: You can adjust the swing speed, swing width, right and left stop time, center

position and swing mode.

6. Technical parameters :

7 .Installation :

Project Content

Remarks

Model ED-100B-P

carriage

Size 380 x160 x 310 W×L×H

Weight 7.5Kg

Travel Rack and pinion

Torch

adjust

Up, down 60mm

Left, right 60mm

Operation angle ±45°

Running angle ±10°

controller

Power AC 36V Provided by power adapter

Size 210 x140 x125 W×L×H

Weight 1.95Kg

Operation

function

Power switch

Power indicator

Start button

Stop button

Travel speed 0~990mm/min

Direction select up, down (left, right)

Torch on / off switch Select torch on or off

amplitude of swing ±8°

Swing mode

Swing speed 0~3.5RPM

Center position ±3°

Left stop time 0~2S

Right stop time 0~2S

Track

form Removable magnet

size 92×2 ×1800 W×H×L

material 65Mn Quenched, galvanized

Bending

radius

R≥1.5M

weight 3Kg Including 10 sets of powerful permanent magnets

Adapter

Input&

Output

Input is AC 220V; Output is AC 36V

Size 200×150×130 L×W×H

Weight 2.4KG Without cable

ED-100B-P Carriage

3

(1)Tools ready

-- Welding power source and wire feeder unit;

-- AC 36V power;

-- CO 2 cylinder;

--Torch for CO 2 ;

--Other necessary tools

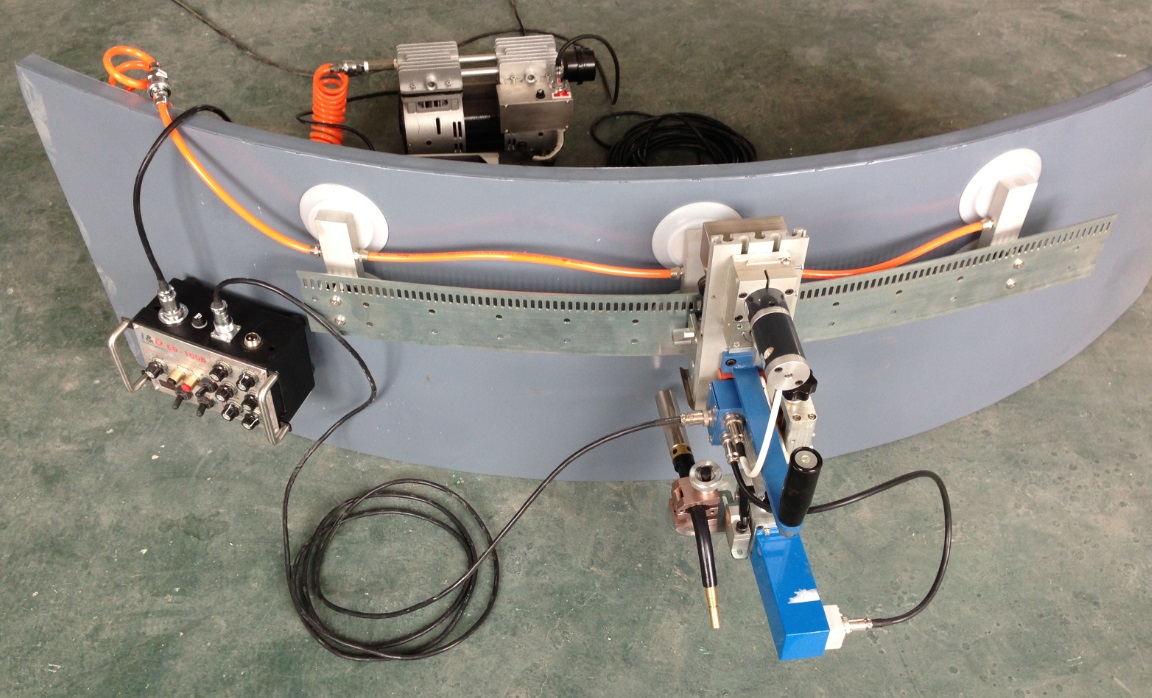

(2)System connection (seen picture)

--Install track and must ensure welding direction parallel to the weld;

--Install carriage: Put the carriage on the track, and drive motor side near the rack side, then close hold clutch

to hold the car on the track tightly and close the drive clutch at the same time. Loosen the locking screw which

used to strengthen support mechanism, and drop the guide wheel to the work piece surface, then lock

screw(see figure bellow).

--Install wire tray and pull wire to the torch end;

-- Torch port connect to the wire feeder

ED-100B-P Carriage